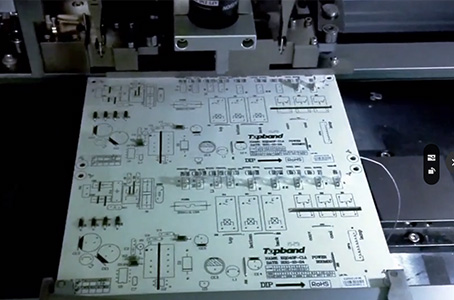

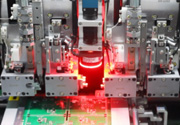

Special-shaped insert machine is suitable for capacitors (electrolytic capacitors, safety capacitors), DIP package ics, connectors, transformers and other types of special-shaped components. Easy to use, 20 minutes to change the line. Diversified feeding institutions. The number of plug-in axes is customized. Simple operation, convenient installation and space saving. Easy to automate production lines and factory operations. Comprehensive and fast replacement of labor, saving a lot of labor.

At the same time, the special-shaped insert machine also has the following functions:

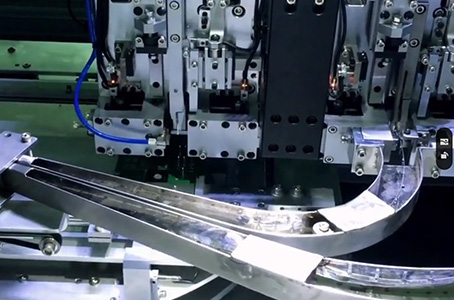

First, it can realize the automatic insertion of parts of different sizes and shapes, and its technology is characterized by the various specifications of bulk materials or plug-in and other shaped electronic components through a special feeder or vibration disk directional ordering and delivery to the machine, and then by a specially designed plug-in head to absorb or clamp, to achieve plug-in speed can replace several skilled manpower.

Second, the special-shaped insert machine is independently controlled through the modular design concept of the main engine and the feeding device. It can realize rapid replacement and alignment, provide a variety of feeding schemes according to different incoming materials, and flexibly configure according to production needs to meet the continuous feeding of pin components and irregular components; All feeders are equipped by the shaping device. The forming and shaping device of components can reduce the requirement of incoming materials, improve the universality and compatibility of equipment, and improve the insertion rate of components; Provide customized services through a wide range of pickup devices.

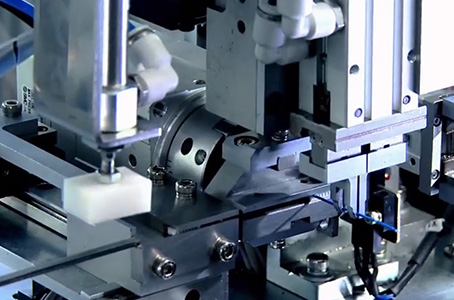

Third, a complete range of mouthpieces and claws can meet the connectors, relays, transformers and other special-shaped components to pick up to meet the customized needs of special components; Through advanced vision algorithm to achieve high-speed photography. The visual algorithm created for the shaped plug-in can accurately detect and locate the PIN quality, appearance contour, and coordinate position of the component.

In short, the special-shaped insert machine is a new type of automation equipment, which can provide professional solutions in the field of robot application and automation to replace manual labor, generate power through electric and pneumatic means to replace frequent manual tightening action, in terms of manual aspects and production efficiency, reduce the work intensity of the lock plug-in, while improving work efficiency and effectively reducing costs. At present, China's domestic special-shaped insertion machine such as Chuangda and other brands have won the favor and praise of many customers, and the products are exported to the world.

Yield >99.7%, insertion accuracy ±0.02mm.

The above is about the morning function of the special-shaped insert machine.