How to use the foot cutting machine safely

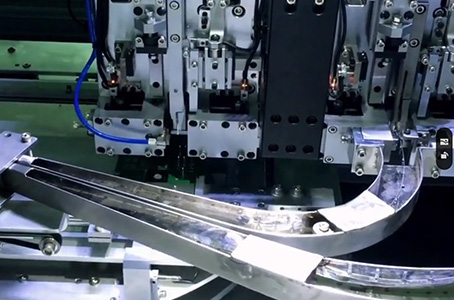

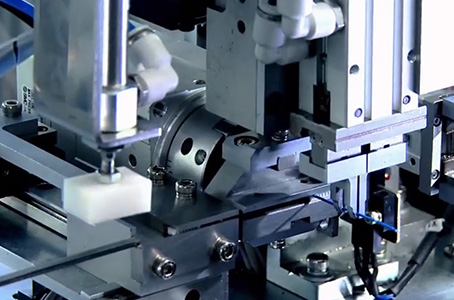

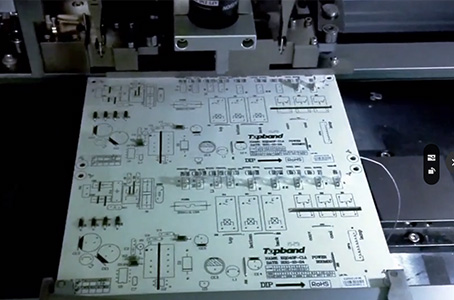

What is a capacitor foot cutter? It is to cut off the pin of the truncated capacitor according to the specification, in order to make the capacitor more suitable for automatic welding of the pipeline and improve the efficiency of circuit board welding. Capacitor foot cutting machine must pay attention to safety when using, the following is the capacitor foot cutting machine manufacturer according to many years of capacitor foot cutting machine experience collated capacitor foot cutting machine safety precautions.

As far as the current development of China's tool market is concerned, the contribution of tool development to the processing and manufacturing industry is very prominent; However, according to the planning requirements and needs of China's "Twelfth Five-Year Plan", China's tool development still needs to be further improved, mainly in several aspects such as product structure adjustment, tool innovation and industry transformation. In order to meet the needs of the continuous development of the manufacturing industry in the future, these aspects are the main direction of development.

For tool product structure adjustment, this is the necessary stage of future tool development. Tool materials have entered the era of cemented carbide, cemented carbide is known as the teeth of modern industry, compared with high-speed steel, cemented carbide has better performance and higher cutting efficiency, it and superhard tool materials together, is the most important guarantee for modern cutting technology to achieve efficient processing. The proportion of carbide cutting tools in China is about 40%, which is far lower than the level of industrial developed countries, restricting the overall level of tool products in China.

Without good tool materials, any tool innovation and cutting process progress lack the necessary material basis, to fundamentally solve this problem, involving the adjustment of industry structure. Tool innovation is the most important factor to promote the advancement of cutting technology and improve the efficiency of cutting processing. Tool innovation should be developed from the use of material grade optimization innovation, tool coating technology specific cutting innovation and tool structure service innovation. Guided by market demand, based on quality performance, and for the purpose of service cooperation, the company aims to meet the higher requirements of the manufacturing industry put forward by the development of the market economy, so as to promote the development of social economy. The transformation of the tool industry needs to be determined according to the actual situation, and the principle of maximizing the utilization of resources to promote the healthy development of the tool market.

1. It is strictly forbidden to put your hand into the machine when the capacitor foot cutting machine is moving, which is very dangerous (light rolling fingers).

2. Do not open the cover when the machine is running.

3, non-professional maintenance personnel, do not remove the boot cover for maintenance.

4, the machine should not be used in flammable, corrosive, humid, high dust and other harsh environment, wet corrosion environment will damage the capacitor foot cutting machine.

5, to prevent electric shock, the machine must be well grounded in the case of work.

6. When loading and unloading blades or encountering abnormal conditions, please cut off the main power supply.

7, in case of power failure, please cut off the main power supply.

The varieties of foot cutting machine in our factory can meet the different needs of different consumers, and improve the appearance of the foot cutting machine as much as possible, and establish the image of the knife sharpening machine in consumers. Improve the human-machine interface, enhance the convenience, comfort and safety of the foot cutting machine operation.

The foot cutting machine with high power, high precision and high degree of initiative has broad market prospects and abundant profits, which is the main development direction of the foot cutting machine in our factory.