- Product sample

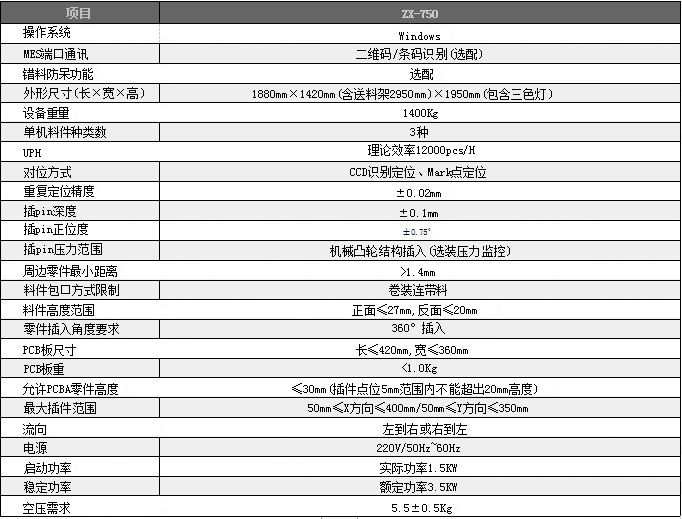

- Technical specifications

- Equipment details

- Feed method

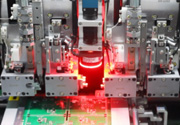

- Video display

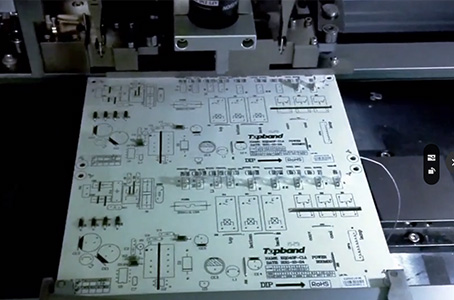

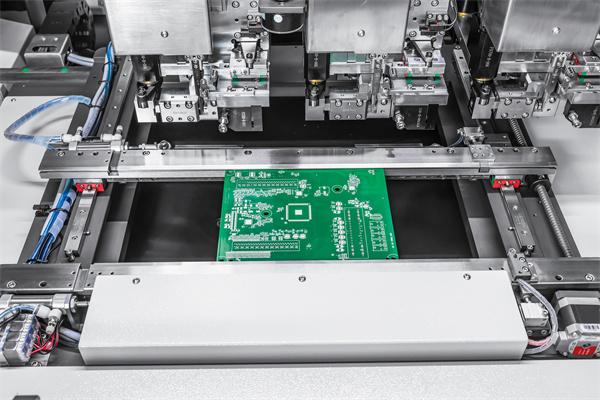

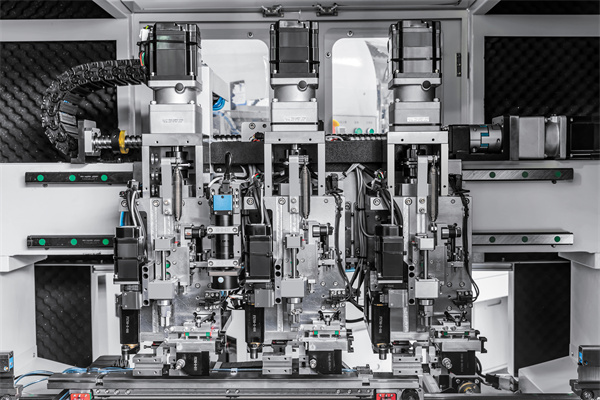

Work platform

◆ Ejector rod design and compatible with pressure monitoring device.

◆ Workbench adopts gripper to take the board, with the board positioning function.

◆ Workbench with circuit board detection function.

◆PCB multiple positioning, to ensure the board positioning accuracy.

◆ Automatic adjustment of track width (optional).

◆ Maximum board size 420×350mm.

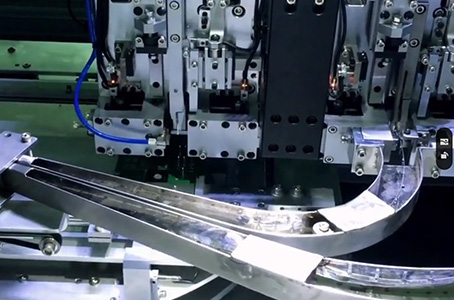

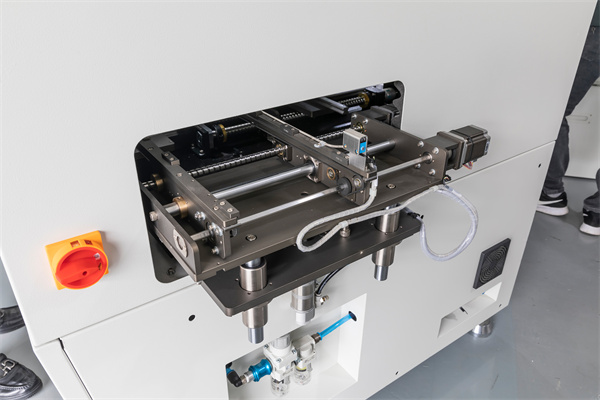

Quick loading feeding mechanism

◆ Modular servo drive.

◆ No need to adjust the cable change.

◆ Fast disassembly design, simple wire change.

◆ Lack of material alarm detection function.

◆ New design, stable and efficient, reduce material loss

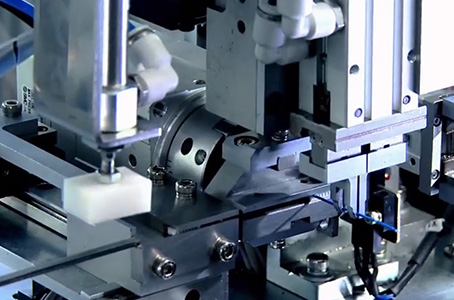

◆ Multi-head combination: 1-3 head combinations can be realized, with one-key on/off plug-in head function.

◆ 0.64Pin pin can realize the function of 3 pins, improve efficiency.

◆ Plug-in Angle head automatic adjustment, programmable setting.

◆ MES system, barcode scanning record: scan PCB barcode, record production data, insert depth data, easy to trace (optional).

◆ CCD identification, Mark point identification, accurate positioning, efficient production.

◆ Integrated frame design, more stable, more efficient.

◆ One-click adjustment of track width, more convenient and intelligent.

◆ Stepper motor drive, precise position.

◆ Track stop detection function, automatic PCB transfer.

◆ Anti-static belt.

◆ Simple structure, easy to maintain, the equipment program software can set the track width data, can realize the automatic adjustment of the track width (optional), the operation is simpler.